- Home

- CSR

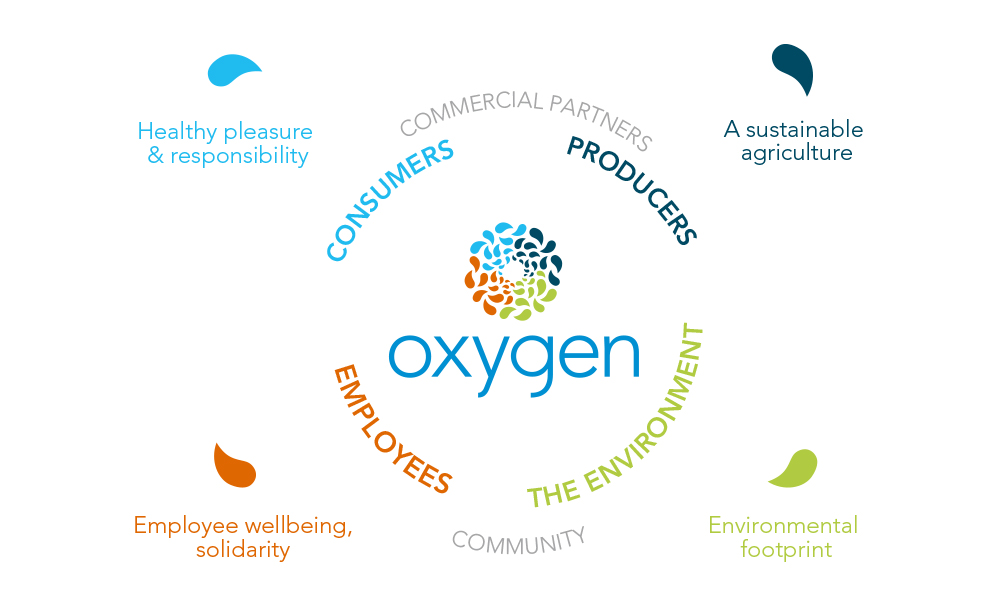

- Our CSR Approach

- Environmental footprint

Rethinking the energy mix

Convinced that the climate is an ally for its brands and aware of global issues related to greenhouse gas emissions, Savencia places decarbonization challenges even more at the heart of its growth model. Reducing our energy consumption, increasing the share of renewable energy sources, and lowering greenhouse gas emissions in transportation by favoring biofuels across all our activities, especially in our milk collection, are actions we have already undertaken and will continue to develop.

Savencia is decarbonizing its sites

Since 2021, Savencia has been strengthening its decarbonization plan in its cheese factories in France. The idea is simple: to recover lost energy, especially the heat generated by refrigeration processes, to produce hot water and thus reduce gas consumption in boilers. In total, 14 projects across 13 French sites have involved engineers, technicians, employees, as well as suppliers and partners, resulting in a 25% reduction in greenhouse gas emissions and a 15% reduction in energy consumption.

Always more eco-designed packaging

Tartare, Apérivrais, Révillon, Elle&Vire, Coraya... a shared commitment in favor of eco-design for packaging that is more environmentally friendly, with a goal of 100% recyclable or biodegradable packaging for its products by 2025.

“En route” for the circular economy

What if the industrial waste from our manufacturing facilities could be used to fuel the circular economy? In the framework of our CSR approach, several of our subsidiaries already make use of methanization, a biological process in which organic matter is broken down by bacteria with a total absence of air or oxygen, thereby producing energy. The Group’s Fro’ subsidiary thus recycles 100% of its organic waste using its milk producers’ methanization equipment, while the Azé cheese plant in France’s Mayenne department has set up a local partnership for methanization of its own organic waste: many local virtuous circles which contribute to minimizing the environmental impact of our industrial operations.